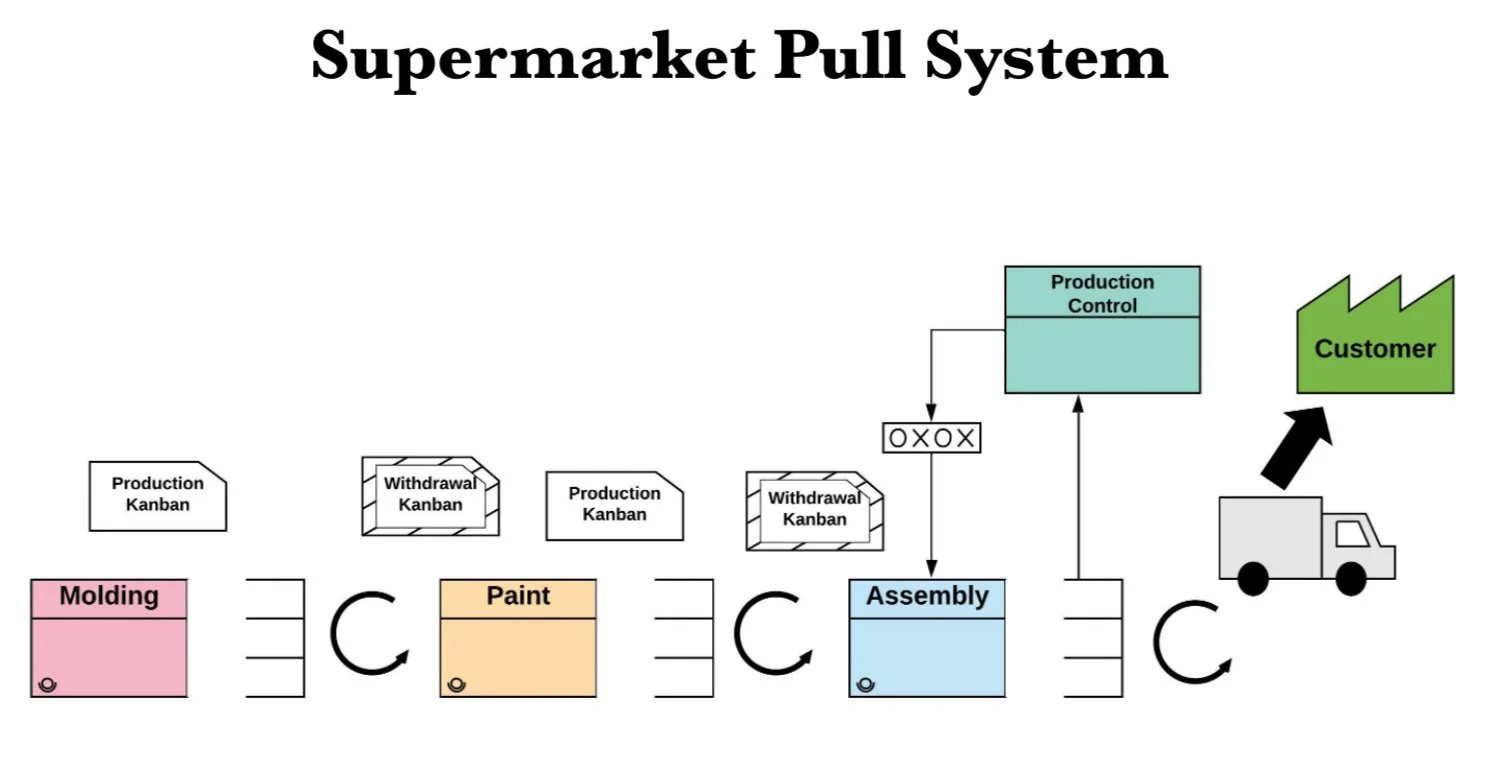

Supermarket pull systems stabilize flow by replacing forecasts with simple, visible rules tied to actual consumption. This article explains how they work, where they fit, and why they still matter in real operating environments.

Read MoreThis article marks Part I of my two-part series exploring Edward de Bono’s Six Thinking Hats framework.

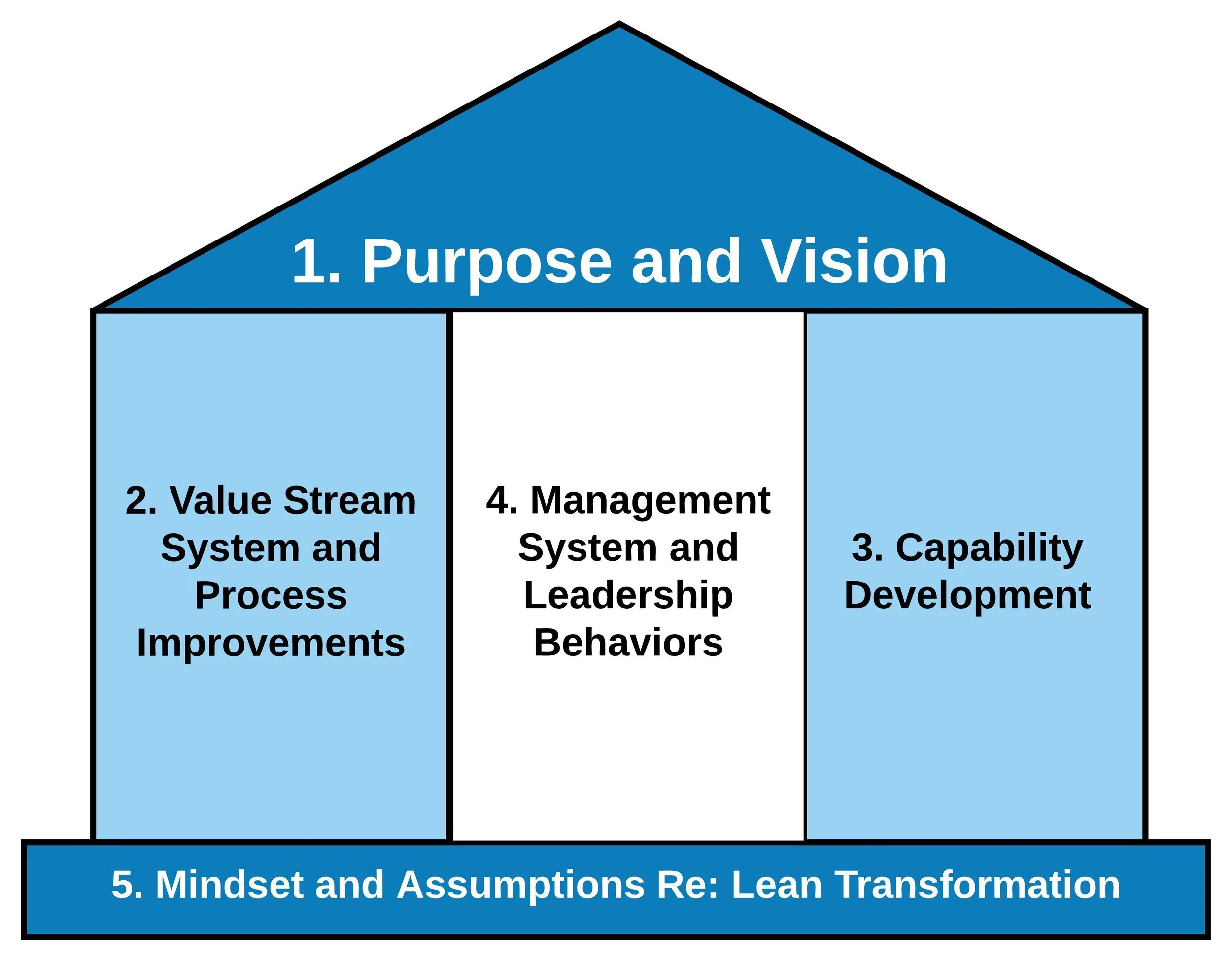

Read MoreEmbarking on a Lean journey is a transformative endeavor that requires courage, dedication, and a willingness to embrace change. While the path is strewn with challenges that test an organization's resilience, the pursuit of Lean principles leads to profound rewards: fortified resilience, groundbreaking innovation, and sustainable growth. Drawing on my experience in helping organizations implement Lean at the enterprise level, as well as insights from other industry leaders, including a thorough analysis of an exemplary transformation model, this article will delve into best practices and proven strategies for successful Lean transformations.

The Lean Transformation Framework, developed by the Lean Enterprise Institute, offers a comprehensive roadmap for navigating this complex journey. Illustrated through the visual metaphor of a house, the framework delineates the fundamental dimensions essential for orchestrating effective enterprise-level change.

Read MoreDiscover how Pixar Animation Studios and their beloved character Remy from "Ratatouille" exemplify the power of Kaizen—continuous improvement and innovation. Learn how small, consistent enhancements and groundbreaking ideas drive creativity and success in both animation and culinary arts. Uncover the secrets to thriving with Kaizen and innovation.

Read MoreIn a scenario reminiscent of Office Space, Milton Waddams, who treasures his red Swingline stapler as much as Hank Hill loves propane and Beavis loves heavy metal, presents a meticulously thought-out improvement suggestion to address the issue of his stapler constantly going missing. However, his suggestion to add an electric shock feature to deter theft, while creative, is not viable due to safety concerns and practicality.

Read MoreImagine being in a high-stakes environment where a single misstep could lead to catastrophic failures, impacting not just the bottom line but, more critically, people's lives. In the world of medical device manufacturing, precision isn't just a goal—it's a necessity. Yet, what happens when processes falter and defects creep in? Before we jump to quick fixes, we need to take a step back and dive deep into the root causes. Just as the iconic characters of Seinfeld navigate their misadventures with varying degrees of success, so too must we meticulously uncover the underlying issues behind production failures. In this essay, we'll explore Root Cause Analysis and the 5 Why Approach, using a touch of Seinfeld humor to make the journey both enlightening and entertaining.

Read MoreIn the pursuit of continuous improvement, companies often focus on short-term cost savings and specific tools, leading to temporary fixes. True success, however, comes from a holistic, systems-thinking approach. By examining interconnections within an organization and optimizing these links, businesses can build a resilient, effective, and innovative future. Discover how this mindset, illustrated through vivid healthcare examples, fosters sustainable growth and excellence.

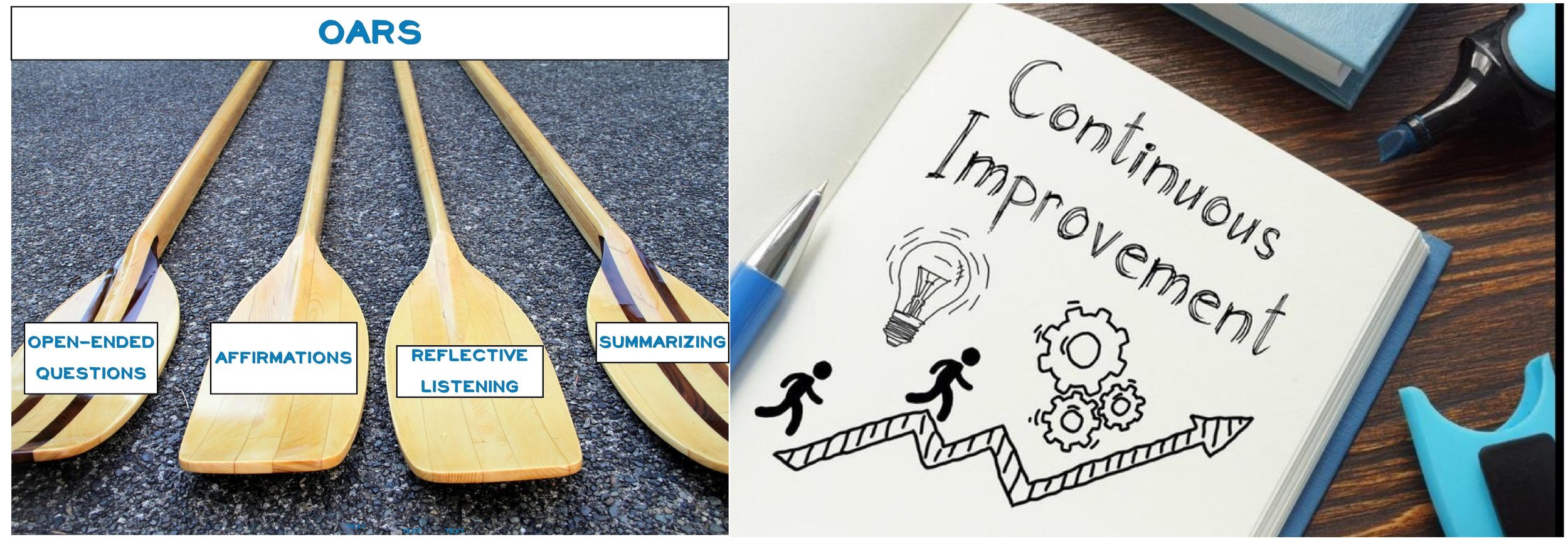

Read MoreNavigate the roaring rapids of change with OARS—Open questions, Affirmations, Reflective listening, and Summarizing. Discover how these motivational interviewing techniques can help leaders steer their teams through resistance, foster engagement, and drive successful transformations. Improve communication, strengthen relationships, and boost morale for a vibrant, positive workplace culture.

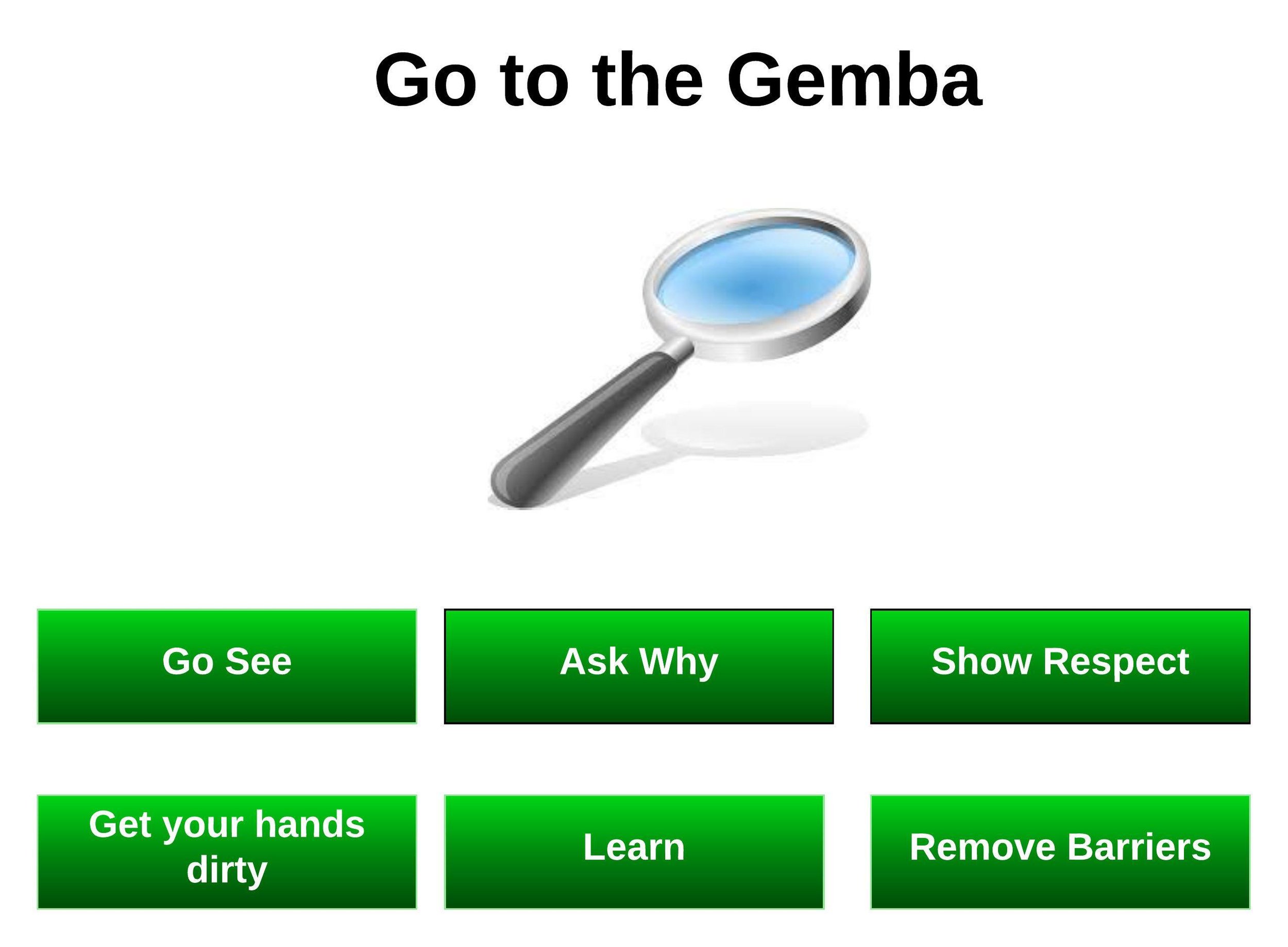

Read MoreThe Lean leadership principle of "Go to the Gemba" embodies the essence of Theodore Roosevelt’s famous "Man in the Arena" speech. Roosevelt emphasizes the honor and value of being actively engaged in the struggle, rather than remaining a passive observer. Similarly, "Go to the Gemba" encourages leaders to step onto the front lines where the real work happens, gaining firsthand insights and understanding.

Read MoreI had the pleasure of helping facilitate a kaizen event at our member organization Tactical Air Support on Friday. The group targeted specific areas to improve the flow of information from leadership to front-line workers, with the execution of the improvement plan already underway.

After completing the session, I toured the hangar and was excited to see a recent addition to the facility's visual management system. This board is located in an easily visible location and supports the company's unwavering commitment to fostering a safety first culture.

Read MoreECRS is a simple four-step problem-solving technique for teams seeking ways to improve the quality, delivery, cost, and safety of a key process. E refers to eliminate, C to combine, R to rearrange, and S to simplify. By applying these four steps, work teams can create smoothly flowing value streams. Since the illustration above reminded me of the iconic shot of the horizon that closed out A New Hope, I thought it would be fun to adapt ECRS to the processes featured in the Star Wars universe. Process improvement is sorely needed in this bureaucratic galaxy.

Read MoreThink of an organization like a Formula 1 team. If the car isn’t performing well, it’s not just about the driver. It could be the aerodynamics, the engine tuning, or the pit stop strategy. Similarly, in a company, while employees might need fine-tuning from time to time, it’s the systems and processes that usually require a more significant adjustment.

Read More