A3 Guided Questions for Approved Bright Ideas Cards

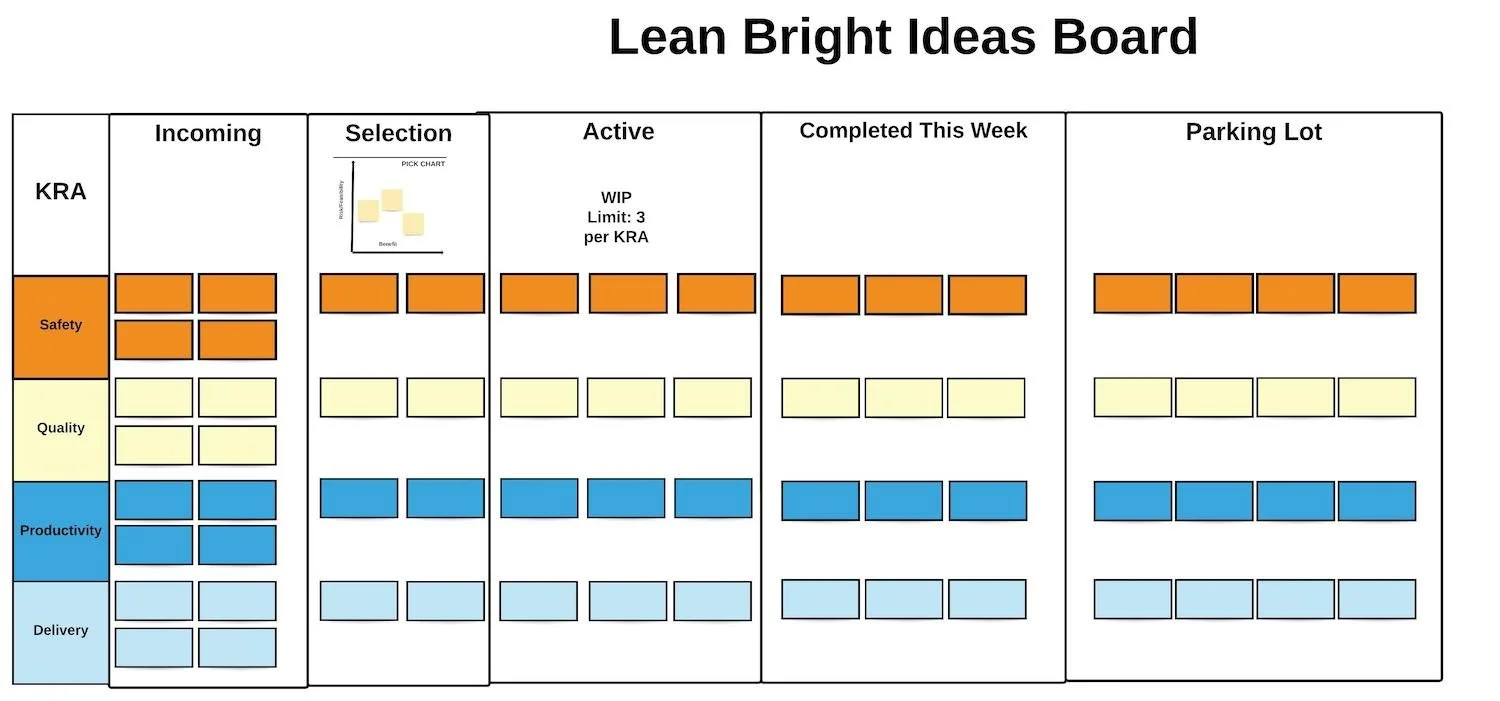

Bright Ideas provides a structured, visual management system for employee suggestions—creating an effective, low-cost way to actively engage employees in continuous improvement activities, while ensuring all improvements are aligned with the organization’s key strategies.

We recently re-published a blog post on our step-by-step guide for implementing this system at your company.

For each approved card, the reviewer will assign the submitter with the task of creating an A3 to guide and summarize their problem solving effort.

A3 Problem Solving is a Toyota-pioneered problem-solving practice of gathering the problem, the analysis, the corrective-actions, and the action plan down on a single piece (11 by 17) of paper. A3s serve as the standard work document that guides overall strategy, problem-solving exercises, project status reporting, value stream mapping, rapid improvement events, coaching, goal setting and all other Lean improvements. A3s help teams follow the scientific method and improve their work through experimentation, direct observation, root cause analysis, brainstorming, implementation, and follow-up.

At Lean Jax, we recommend our members use DMAIC to structure their improvements and corresponding A3s, as it is clear and easy to follow. You can download a pdf A3 template here.

Now, let’s take a look at the guided questions for completing an approved Bright Ideas card’s corresponding A3. Additionally, you can download a copy here.

I. Define

1.1 What problem (gap from standard) do you want to address?

1.2 Does this problem impact any of the organization’s key result areas? (Safety, quality, cost, delivery, or morale?) If so, to what extent?

1.3 Why is it important to address this problem? (Scope? Impact? Trend? Urgency?)

II. Measure

2.1 Did you discover any examples of the 8 wastes? If so, which ones?

2.2 Visually show evidence of the problem with charts, diagrams, graphs, pictures, drawings, etc.

2.3 Did your initial perception of the problem change after observing it at the Gemba? Why or why not?

2.4 What are your specific improvement goals? Target condition: Key Result Area, Current Condition, By how much? By When?

III. Analyze

3.1 Brainstorm contributory causes of the problem and organize them into applicable categories on a fishbone diagram.

3.2 Use 5 Whys to dive deeper and discover the problem’s root causes.

3.3 List the identified root causes.

3.4 What ideas do you have to address these root causes?

- Can you apply ECRS, mistake proofing, 6S workplace organization, standard work, set up reduction, pull, or training?

IV. Improve

4.1 Prioritize your improvement ideas and select the ones you want to try.

4.2 Create an improvement plan from your selected ideas.

a.) What are the action items? b.) What is the best sequence? c.) Who is responsible for each action item? d.) What resources/ support do you need? e.) When is each action item due? f.) What is the status of each action item?

V. Control

5.1 When will you know if your improvement plan was successful?

5.2 When will you review the status of your improvement plan? Who will you review it with.

5.3 After reviewing the status, do you need to adjust your improvement plan based on what you learned?

5.4 Did you achieve your improvement goals? Why or why not?

5.5 Visually depict improvement plan results with charts, graphs, pictures, drawings, etc.

5.6 What did you learn? Would you do anything different next time?

5.7 Celebrate success!

5.8 What’s next?

Summary

A3 problem solving provides everyone in an organization with the capability to deliver exceptional customer value, improve their work experience each day, and drive impactful results

By incorporating A3 problem solving into the employee innovation process, companies can build the internal problem-solving capability, accountability, and culture of discipline necessary for operational excellence.

Lean Jax and our member organizations would love for companies applying Lean from around the country to share their experiences implementing sustainable employee suggestion systems. Please reach out to us if you’d be willing to discuss your implementations and share your lessons learned with our community.

#brightideas #employeesuggestionsystems #leanthinking #continuousimprovement #operationalexcellence #a3 #a3problemsolving #scientificthinking #dmaic #leanjax #respectforpeople